A T5 Overdrive in my 1935 Plymouth

Several Mopar flathead owners have asked me about how much trouble it is to install the T5 behind the flathead sixes using the KVC Products (now RUSSELL'S AUTOMOTIVE) T5 adapter kit. Well, I did it in 16 days so I imagine someone with a hoist and more tools than me could do it quicker. I farmed-out the welding, drive shaft construction, and transmission work.

I had been driving my old original, unrestored 1935 Plymouth 4 door Touring Sedan on long trips and having a great time! However, I wanted to cut down my driving time and up my MPH so that I could comfortably travel more than 500 miles per day.

After a review of several web articles and talking to experienced T5 swap guys, like Don Coatney and Tom Langdon, I settled on using a Mustang WC T5 with the longer input and the 3.35 first gear. This box has a .68 fifth gear, which the flathead can handle. While the Mustang swap is more expensive, it requires less drastic trimming of the rear motor mount brackets and insulators on 1935 to 1937 cars. The round biscuits used from 1938 up make the installation much easier. However, my decision to use the Mustang T5 meant that I would have the expense of a donor S-10 T5 for the tail housing, shift cover and rails and the speedo drive gear.

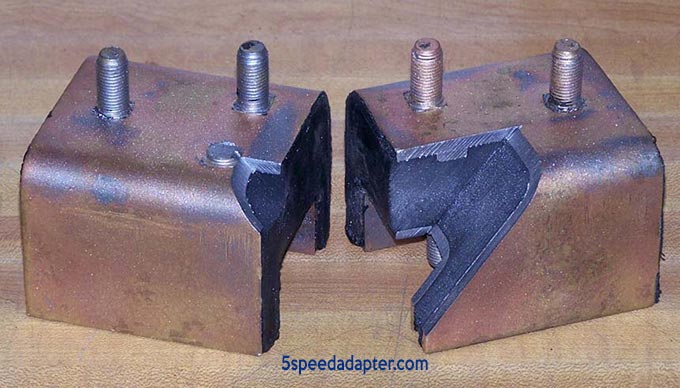

Both rear motor mount brackets and insulators on the ’35 to ’37 models must be trimmed to clear the Mustang adapter plate.

The two bolts holding the brackets to the clutch housing are intact but one of the three insulator studs was lost in the trimming. The S-10 adapter eliminates one of the two bracket-to-clutch housing bolts holding each bracket on ’35 to ’37 cars.

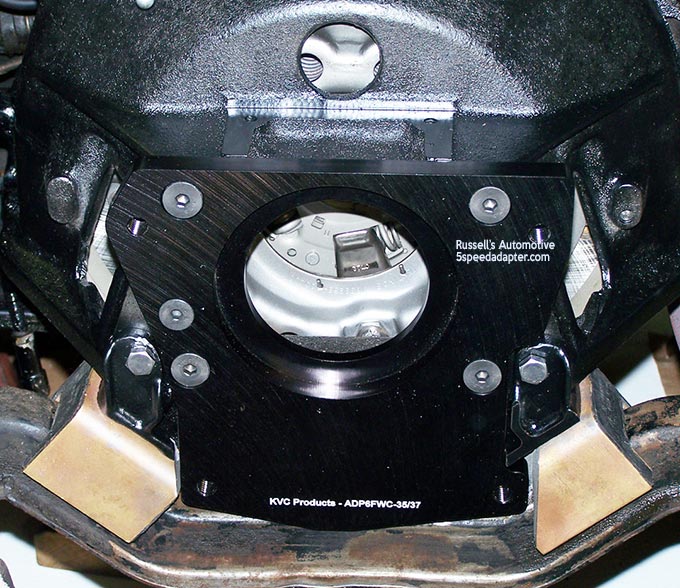

I learned that the rear edge of the adapter plate touched the crossmember so I had to modify that portion of the lower edge. This change has now been incorporated to the adapter design.

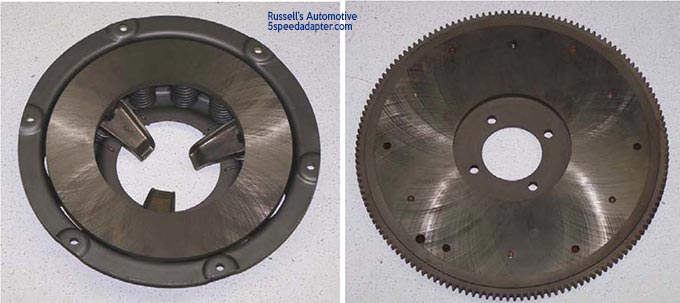

I also took my flywheel and pressure plate to the clutch rebuilder for resurfacing and to install a new ring gear that I found on eBay. The clutch chatter I experienced for the last two years is gone. I can use a stock 9-1/8” X 10 spline clutch disc with this gearbox.

One benefit of the Mustang box is that the bearing retainer will accept Russell's Automotive TBA6MUS throwout bearing & sleeve without any machining. The sleeve mates to 1942 & up clutch forks, which have a 2” opening. I used a P-15 fork and a TBA6MUS throwout bearing in this installation.

The T5 is almost 24” long so it will extend into the X-member on early cars. Because I wanted to install the T5 without having to remove the engine I needed to make the bottom plate of the X-member removable. I did this fairly quick with a cut-off tool and then had two new 1’ X 1/8” straps welded to the cut edges of the piece I removed. I clamped this piece in place and drilled four holes to complete the job.

I chose to add a cross-member to give some added support to the new box. Using a stock insulator from a 68-69 GM product and 1” X 2” X 1/8” wall tubing I found that the new cross member would just about match the lower frame rail of the ’35. I also used some Bear 2 degree spring shims between the mount and the insulator to help get the alignment closer. This will be different on every installation.

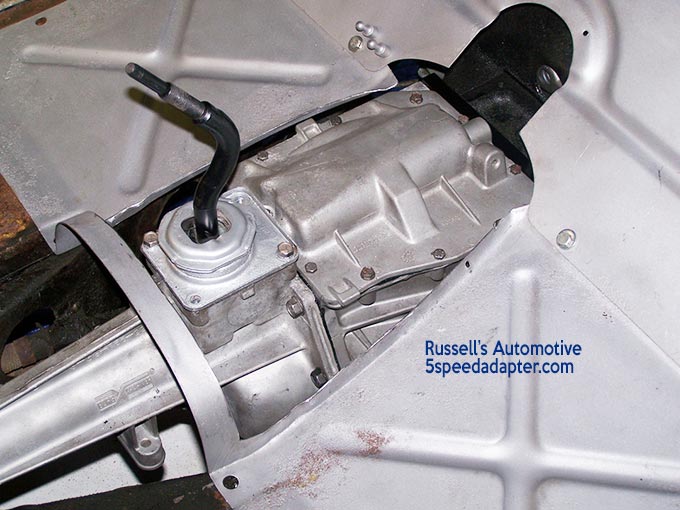

It fits the tunnel without modification. I chose to cut away the top and create a new metal tunnel with a half inch clearance. I could have split the tunnel along the top, spread it open an inch at the front and welded in a patch with the same result. At this point the new tunnel is screwed in place.

The toe board required a patch to cover the hole left by the stock shifter.

The floors have been media blasted and painted with POR-15. New anti-squeak was placed between all floor mounting surfaces.

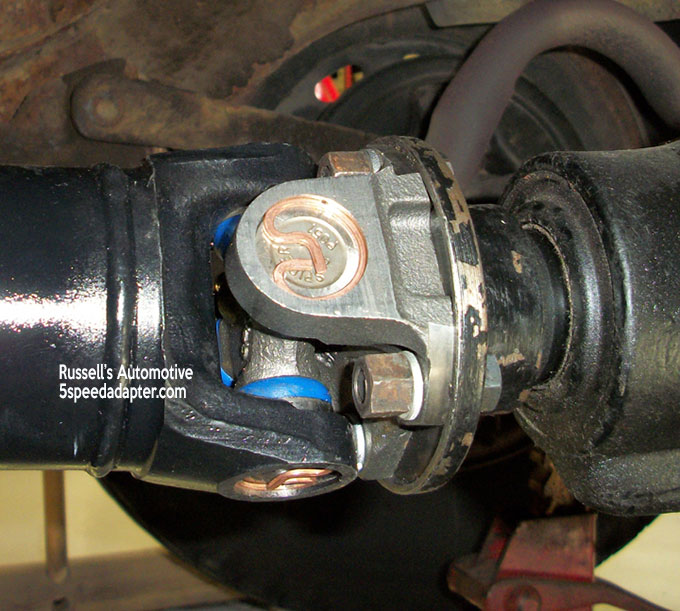

The new drive shaft was assembled in four days by a local truck parts and repair shop. The front yoke is stock Mustang and the rear flange yoke is Spicer 2-2-349. The 1954 Mopar Master Parts List says that all ’35 – ‘54 differential 6-cylinder yoke bolt patterns are the same. So, it appears that this Spicer yoke will bolt up to all the Plymouth and Dodge stock rear ends.

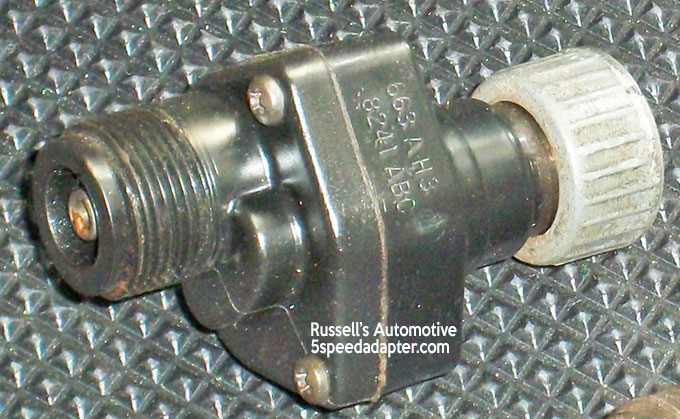

The ’35 Speedo cable was rerouted to the left side where it mated perfectly to the T5. The first test drive showed the MPH to be higher than actual. A Stewart-Warner .8241 reducer was installed on the T5, which brought the MPH to within 2tenths of my GPS MPH at expressway speed! Very fortunate!

Always the big concern with persons considering the T5 swap is the position of the shifter...will it clear the seat? Yes, it will! The T5 shift lever is 12” back from the face of the clutch-housing. In the ’35 that would be 7” from the front seat frame. The shifter is 1” from the seat in 2nd, 4th and reverse.

Before starting this project I took X, Y & Z data from the tip of the stock floor shift lever in neutral. Once the T5 was installed I took the data and found that I needed to use 17” of the stock ’35 shift lever. The angle of the S-10 shifter needed only a 5-degree change to intersect the data point. A very simple jig held everything in place for the welder.

The number one result is that this is a much quieter car now. I didn’t realize just how much noise was coming from the old transmission. Engine rpm noise is obviously reduced too. I can take off with absolutely no chatter, shift up or down with no clashing and do it quicker and quieter than I had imagined. I expect that it will be even quieter after the new floor padding and rubber mat are installed.

Next comes the question of how do I install an emergency brake? Other owners have sent me photos of both mechanical and hydraulic calipers installed on the differential. Here are a couple designs.

Most owners prefer swapping rear ends to get the emergency at the rear wheels. While this takes a little more effort I feel it is actually the better solution as it also gives you a better selection of gear ratios.

For those on a tight budget I recommend that owners of ’38 and newer Mopars use the stock 1989 and earlier S-10 T5 with the mechanical speedo. The ’38 and newer models need only a small piece of the right side, rear mount washer and rubber insulator trimmed. The stock throw-out bearing sleeve can be used by having the sleeve honed to fit the S-10 retainer or have the S10 retainer turned down to fit the stock sleeve. The added crossmember would be optional.

The Ford Mustang adapter can be also be used to mount the ’93-’95 GM S-10/Camaro/Firebird WC T5 by swapping the GM bearing retainer for the Ford retainer.

This article was written by 1935 Plymouth Owner Paul Curtis - used with permission.